Think Smart

Save energy, save money, save headaches

With our efficient and modern machinery,

we add value to the future with quality and

innovation

With our efficient and modern machinery,

we add value to the future with quality and

innovation

PLUS

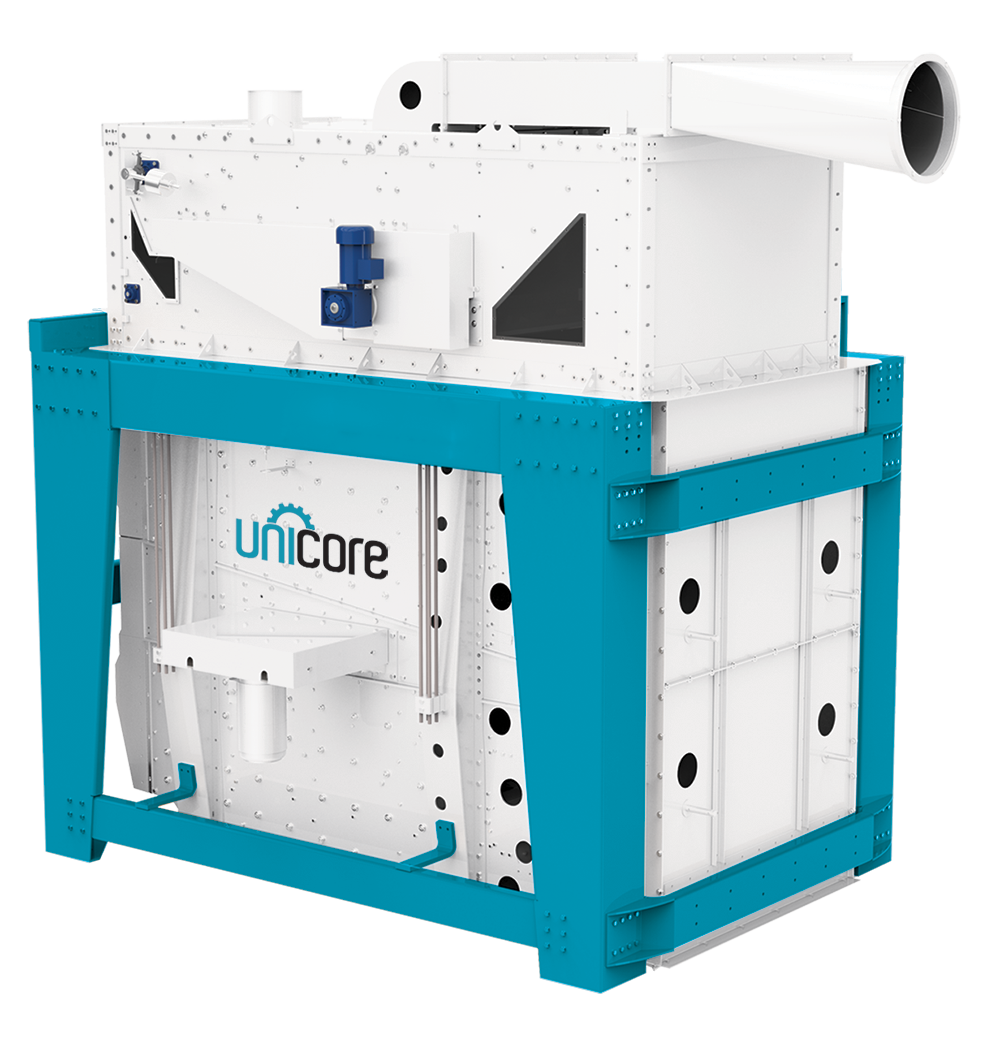

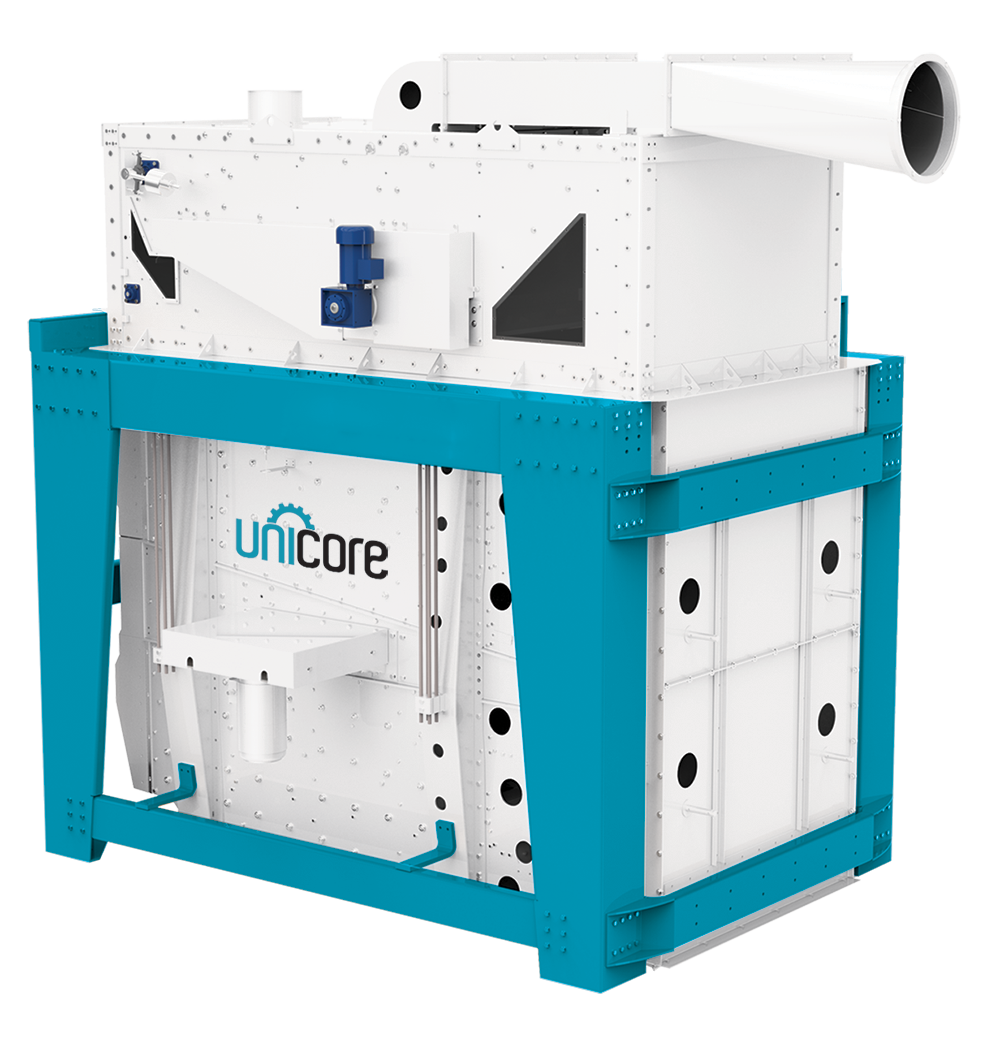

| Type | A | B | C | D | ØF | G | H | ØI | J | K | L | ØM |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UCD-GSH 60 | 3950 | 3170 | 1495 | 2820 | 450 | 2970 | 2335 | 250 | 2280 | 440 | 700 | 200 |

| UCD-GSH 120 | 2310 | 3130 |

| Type |

Air Requirement (m³/dk) |

Sifting Area (m²) |

Sieve Dim. (cm) | Capacity (t/h) |

Weight (kg) |

Feeding Motor (kw) |

Aspiration Group Motor (kw) |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Width |

Length |

Pre-Clean | Cleaning | ||||||||

| Wheat | Corn | Wheat | Corn | ||||||||

| UCD-GSH 60 | 230 | 12 | 150 | 2x100 | 60 | 50 | 45 | 40 | 5900 | 2.2 | 1.1 |

| UCD-GSH 120 | 230 | 24 | 120 | 100 | 90 | 75 | 7500 | 4 | |||

MAIN

Effective cleaning with air is provided both at the product intake and at the cleaned product outlet on the machine.

The drive of the grain waste output conveyors and the grain feeding table is provided by using a single motor with a timing belt and pulley system.

The machine makes circular movements to clean the grain by means of the eccentricweight drive system.